Contents

What Is a Crankshaft?

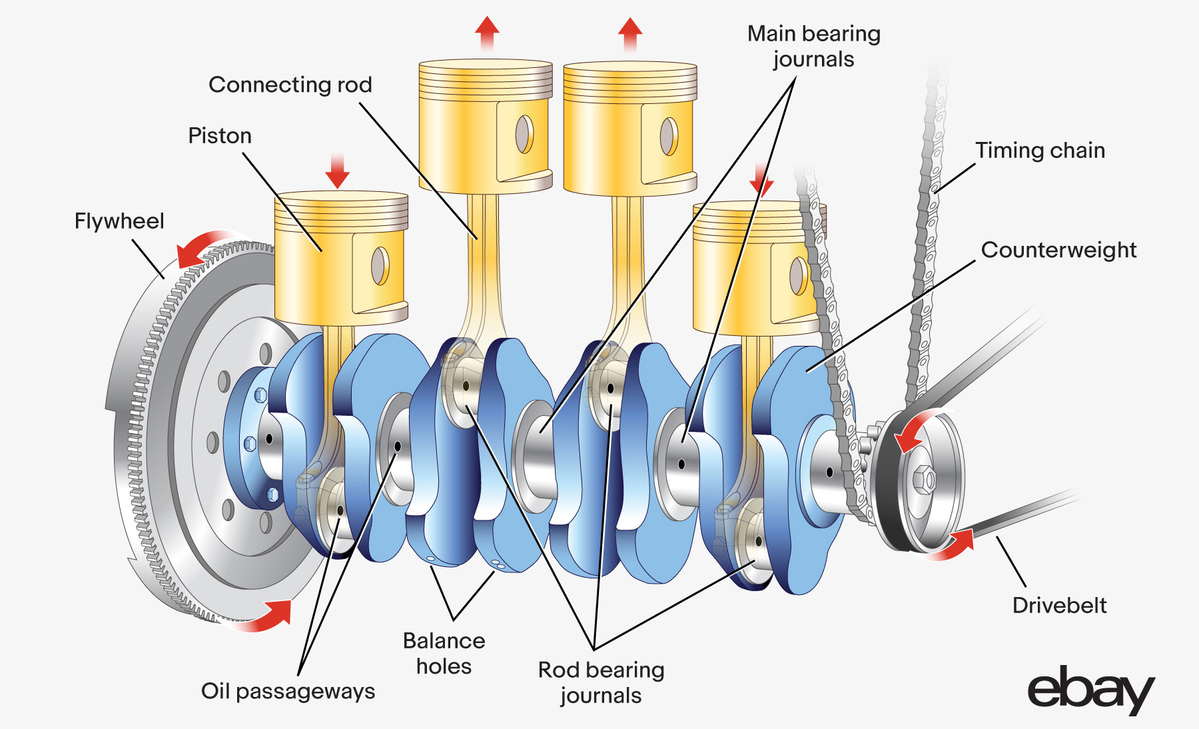

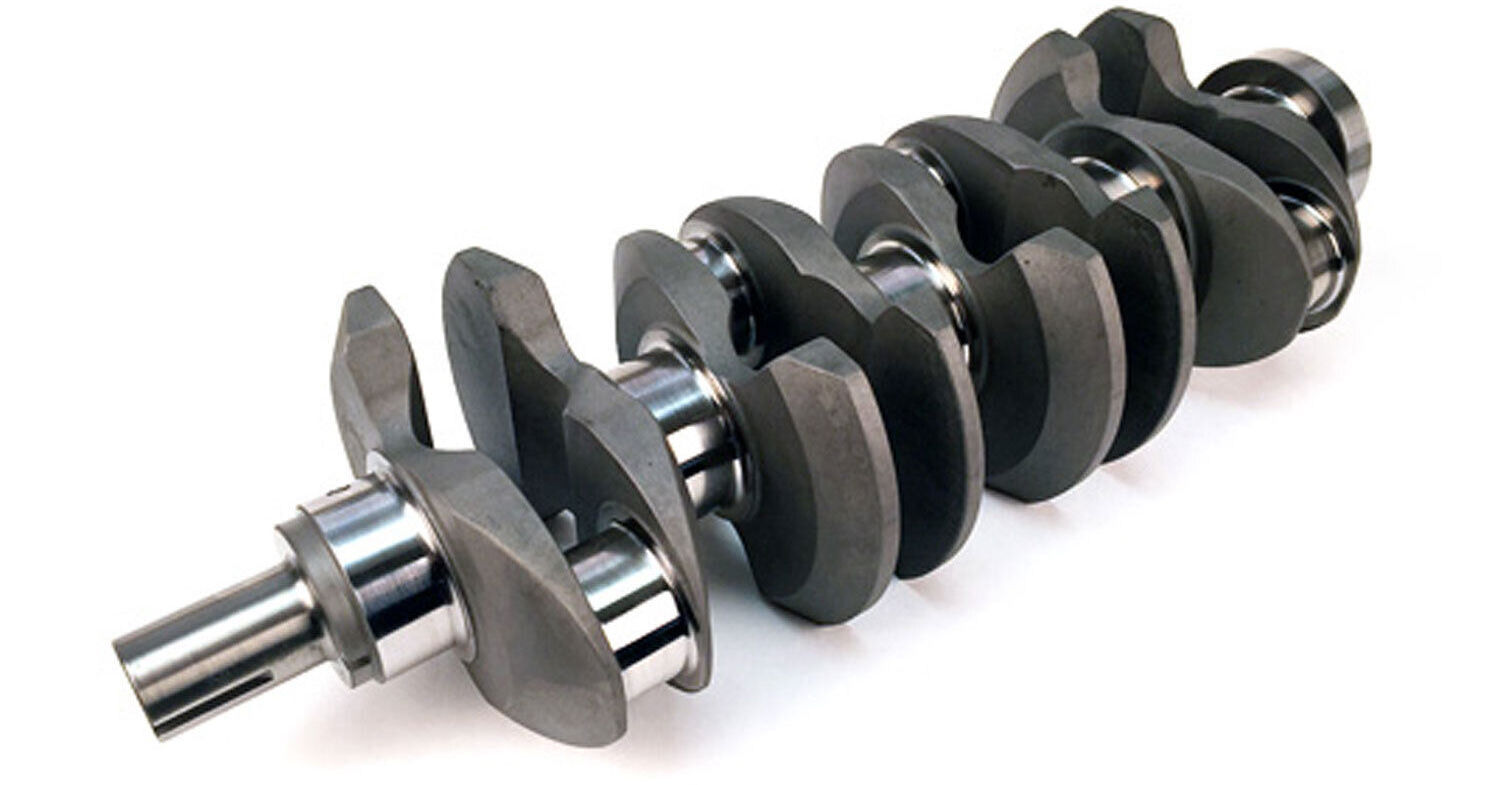

The engine crankshaft is located on the bottom of a vehicle’s motor. It’s responsible for converting the in-and-out reciprocating movement from the pistons into the rotational motion that drives the wheels with the help of a gearbox. Crankshafts have been used in sawmills, water mills, paddle boats, and other devices for centuries.

The modern crankshaft has evenly spaced throws. The term throw is used to describe the measurement between the center of the crankshaft and the center of the rod journals. Connecting rods are attached to these throws. In a four-cylinder engine, there are four evenly spaced throws. These throws are offset from the crankshaft’s axis to create rotational energy.

The crankshaft is attached to the motor at every main journal. Main journals provide support, and are the center of rotation for the shaft. These journals turn inside the main bearings.

Additionally, the flywheel and clutch are connected to the rear of the crankshaft. When the clutch or torque converter engages, rotational energy is sent through the transmission from the crankshaft. It also travels through the differential and driveshafts, which force the wheels to move.

Crankshaft Parts

Here are the main parts of the crankshaft.

- Rod-bearing journals – The connecting rod attaches to the rod-bearing journals. It’s also known as the crank pin or connecting rod journal.

- Main journals – The main bearing journals are clamped to the motor. The journals rotate inside the engine block. These journals contain an oil film forced through a hole in the bearing insert and crankshaft saddle.

- Flywheel mounting flange – The flywheel connects to the crankshaft via the flange. When the clutch or torque converter is engaged, the crankshaft spins the flywheel to turn the gears inside the transmission.

- Counterweights – These weights are needed to apply an opposite force to the weight of the pistons and connecting rods. With an opposing force, stability and balance are added to the crankshaft.

- Oil passages/seals – Passages help transfer the oil from the main journals and connecting rod journals to the bearings. A hole is drilled in the journals for this function. The oil pump forces oil into this space to create a thin barrier between the parts. There are two main seals on the front and rear ends of the crankcase. These seals are responsible for preventing leaks.

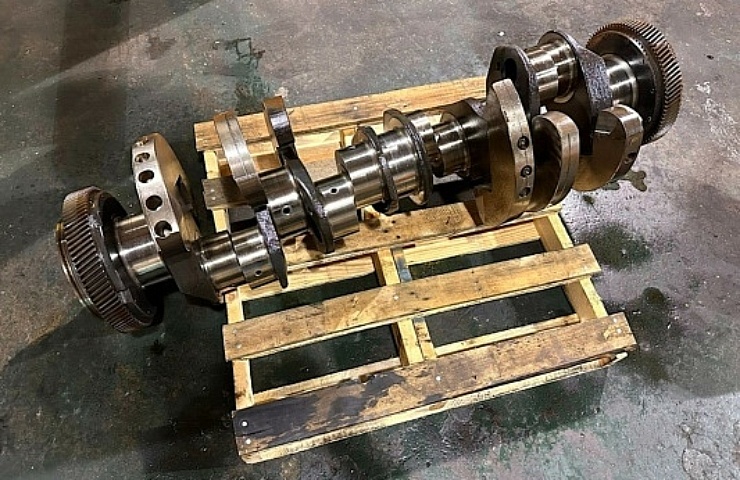

Most crankshafts are made from metal, such as cast iron. A cast is made by pouring molten metal into a mold. Forged steel is used for performance engines. Steel is heated and then formed into the shape by using high pressure. Parts are hardened to withstand the strain and wear of continual rotary movement. This heavy-duty design is meant to last the engine’s lifetime.

The Crankshaft Position Sensor

1998-2010 Toyota crankshaft position sensor

The crankshaft position sensor is an electronic device that monitors the position and rotational speed of the crankshaft. This data is used to adjust fuel injection and other essential engine functions.

The data from the crank sensor is also used with the camshaft position sensor to monitor the relationship between the pistons and valves. This information is vital with variable valve timing (VVT) engines.

Shop now for crankshaft position sensorsTypes of Crankshafts

While the basic design of the crankshaft remains the same, there are different types. Here are designs commonly used in engines, generators, and other mechanical equipment.

Brian Crower Honda K20 billet crankshaft

- Single-piece – This crankshaft is built from a solid piece of material. These are often used in multi-cylinder engines that need moderate and high speeds.

- Built-up – All the pieces are manufactured separately. For example, the crank webs, journals, and pins may be made of different materials and machined alone. The pieces are then shrink-fitted together. After they shrink, a tight grip is formed.

- Semi-built – In this crankshaft, some of the materials are forged together as a whole. Often, the bearing and crank web are shaped and built together. These are commonly used in diesel ship engines.

- Forged – A single metal block is used, so welding isn’t needed. These are used in generators or other applications that operate at medium speeds.

- Welded – All the parts are made separately and welded together. This is a more robust construction than many other types, but manufacturing costs more.

- Cast – Malleable iron is used to make these crankshafts, often found in gas and diesel engine applications. They are cheap and easy to make. The crankshaft is subject to intense heat treatment to improve its strength and reduce wear.

- Billet – Billet is made from 4340 alloy steel, usually containing chromium, molybdenum, nickel, and aluminum. These have a lower machining time and can transfer a lot of power. Minimal balancing is needed.

For the most part, you don’t need to be too concerned about the type of crankshaft in your engine. It’s best to find a direct replacement using what was initially installed.

Camshaft vs. Crankshaft: What’s the Difference?

People get confused about the camshaft when they don’t necessarily understand the difference between these two vital components. They are both necessary parts of the automotive engine.

COMP Cams Ford Mustang Coyote CR series camshaft

- The camshaft is found toward the top of the motor. It’s driven by the crankshaft with the help of either the timing belt or chain.

Camshafts have lobes that open and close the valves. The valves allow air and fuel to enter the combustion chamber. They also allow exhaust gasses to exit after the power stroke during combustion. If there are more valves, additional air and fuel can be added to the engine while more exhaust escapes, thereby creating more engine power.

- On the other hand, the crankshaft is found near the bottom of the engine. It’s attached to the pistons with connecting rods. As the pistons move downward from combustion, the crankshaft rotates.

These two distinct parts work together. While the camshaft controls the valve’s opening and closing movements, the crankshaft takes the energy from this process and helps distribute it to the wheels.

Shop now for camshafts