Contents

How Modern Engines Work

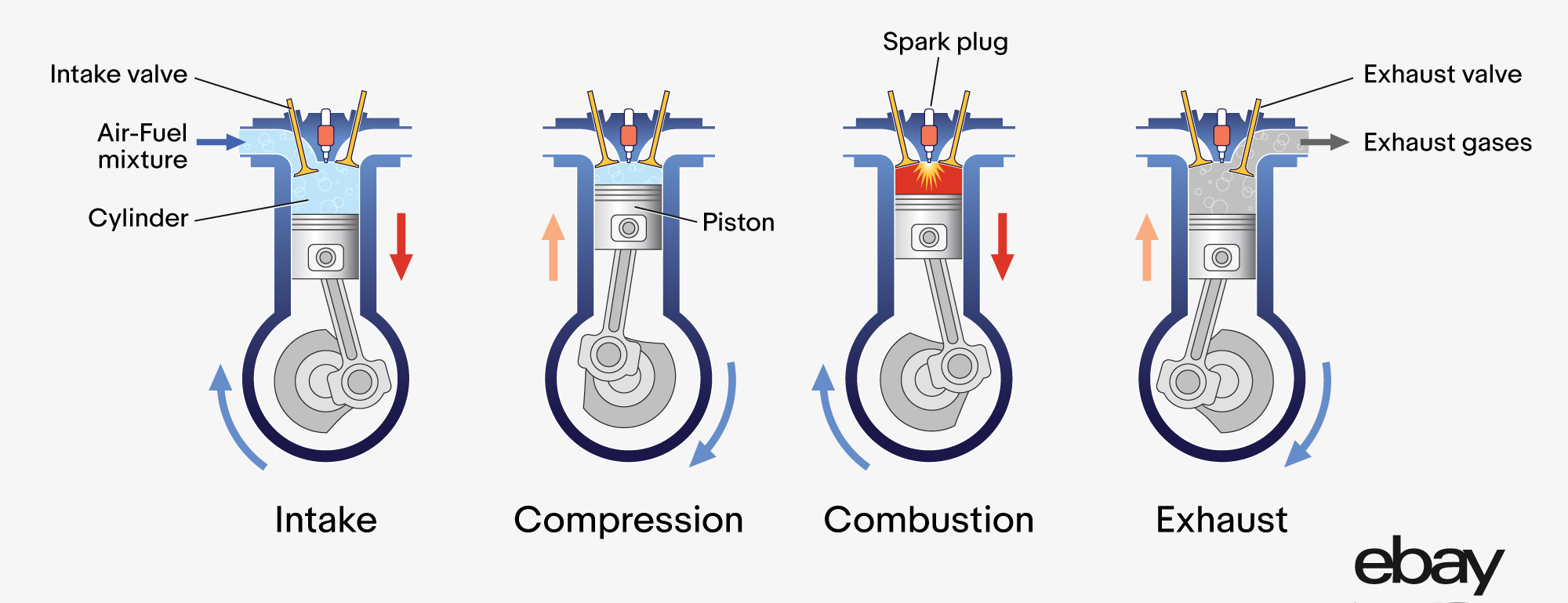

When the car starts, the fuel pump brings fuel from the gas tank through the gas lines to the engine, where it mixes with air. The air-fuel mixture is injected into the engine, where it is compressed by the piston and then set off by the spark plug.

In diesel compression ignition engines, air is inducted into the engine and compressed, with the fuel then sprayed into that hot air, resulting in combustion.

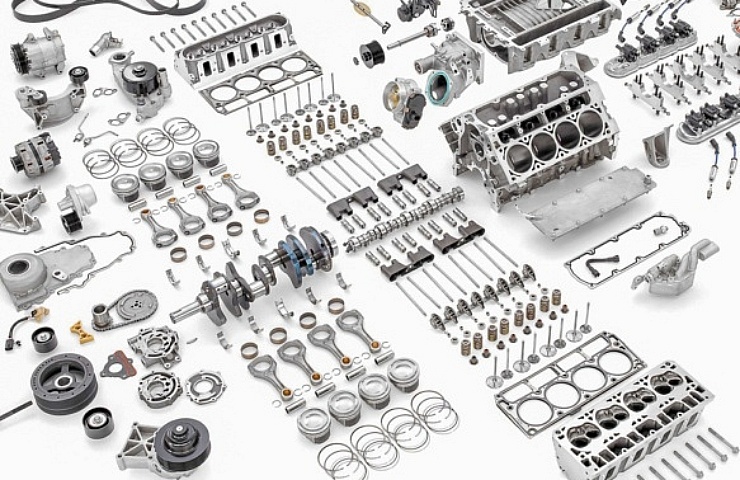

Parts of an Internal Combustion Engine

All these engine parts work together to power a vehicle that can carry a full load of occupants down the road while barely making its presence known in the passenger cabin. That’s thanks to more than a century of refinement to the internal combustion engine.

Crankshaft

The explosion causes the gasses to expand and moves the piston down in the combustion chamber, with the connecting rod delivering energy to the crankshaft. The rotating crankshaft moves the energy through the flywheel to the driveshaft and then to the wheels.

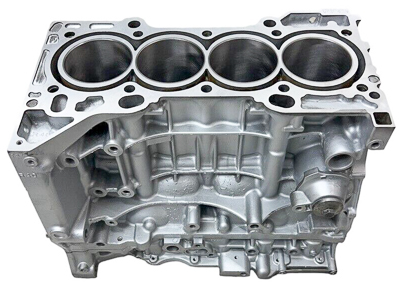

Engine Block

Typically made of aluminum (or cast iron in older engines), the engine block is a single casting that is the heart of the engine, and most other parts mount to it. The block determines the displacement of the engine, often measured in liters. Most engines use either an inline or a V-formation for the cylinders (which allows for a more compact design).

Some Volkswagens, Subarus, and Porsches use a flat or boxer configuration, also known as a horizontally opposed engine.

Although there are working three- and five-cylinder engines, four, six, eight, or 12 cylinders are more common. The V-16 was used on cars in the 1930s but is rare now as engines increase efficiency.

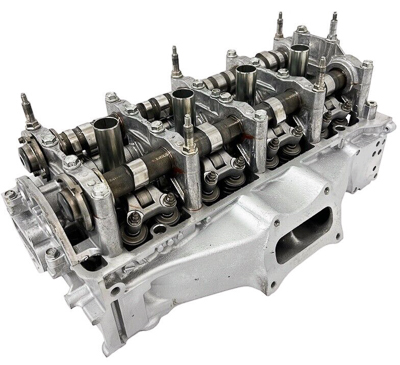

Cylinder Head

Pistons

The driving forces known as pistons are mounted tightly within the engine block’s circular combustion chambers. The piston is connected via a rod that rotates on both ends to the crankshaft, which turns the piston’s linear motion into necessary rotation.

Piston Rings

The piston rings are mounted on the pistons to ensure a tight fit. They prevent the air-fuel mixture and exhaust from leaking into the oil pan.

If your vehicle needs to be regularly topped off with oil, that’s either due to worn rings or an oil leak. Oil is normally stored for recirculation in the sump or oil pan at the bottom of the engine.

Valves

Spark Plugs

These small cylinders are part of the electrical system and provide a timed spark that sets off the air-fuel mixture in the combustion chamber.

The number of spark plugs generally conforms to the number of cylinders, though some engines use a twin-spark arrangement with two plugs per cylinder. Each vehicle has a specific “gap” through which the spark arcs. This must be set for the vehicle to be in tune.

Flywheel

Flywheel

Attached to the crankshaft, the circular flywheel stores rotational energy from the engine. The flywheel is there to perform a balancing act, smooth out the power delivery from combustion, and deliver a better idle. The clutch and torque converter housing are often mounted on the flywheel.

Camshaft

With small irregular lobes mounted on a shaft or rod, the camshaft opens and closes valves according to a set timing. One lobe of the camshaft activates the intake valve, and a second one controls the exhaust valve.

On modern overhead-cam engines, the shaft is mounted in the cylinder head. A dual-overhead-cam (DOHC) engine, like those in classic cars from Lotus, Alfa-Romeo, and Jaguar, has two cams per bank. A four-cylinder DOHC engine has two camshafts, and a V-6 or V-8 has four.

Timing Chain

Fuel Injectors

Fuel injection, which has replaced the less-precise carburetor, delivers fuel to the inlet port or manifold. Fuel injectors send out a fine and precisely metered mist of fuel. The fuel mixes with air before delivery to the combustion chamber.

Early fuel injection systems were mechanical, but today’s units are electronically managed. In cars with desirable direct injection, the high-pressure injector is placed on the cylinder head, allowing the fuel to be shot directly into the combustion chamber.

Engine Maintenance and Service

Ongoing advancements in engine parts make modern internal combustion engines run more efficiently and produce more power than ever. With great fuel economy and horsepower comes great responsibility.

Regular maintenance like changing your oil and replacing the air filter protects the parts in your engine from wear and keeps your vehicle running at its best. Taking care of your engine now can prevent expensive repair bills down the road.

Flywheel

Flywheel