Contents

As an engine builder with many years of experience, I am often asked about the best engine power upgrades. To add grunt, you need to burn more fuel—and to make that happen, you must add more air to the combustion chamber.

Here are four options to get more air to the engine: superchargers, turbochargers, nitrous oxide, and compressed air supercharging. They all increase the combustibility of the fuel being burned. Here’s the rule:

Greater fuel consumption equals higher heat which means more power.

If you have questions for me, please add them in the comments below.

Superchargers

The supercharger, developed in the mid-1800s, was initially used in furnaces. However, the first supercharger tested on a car engine was in 1879. Gottlieb Daimler, who designed the world’s first four-wheeled automobile, received a patent for a supercharger applied to an internal combustion engine in 1885.

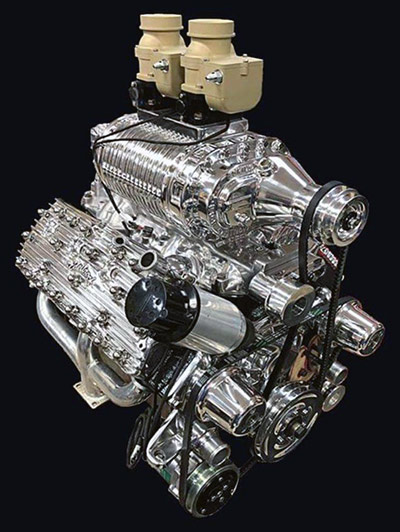

Edelbrock’s 15172 E-Force Supercharger fits the 2015-2017 Dodge Challenger and Charger’s 392 cubic-inch HEMI V-8.

Superchargers are belt driven. They are mechanically connected to the crankshaft, turning two rotors to force air into the engine. If you know how to do an intake swap, you can install a supercharger.

Superchargers were used on Flathead Fords since the early days of racing.

You’ll also need to add a fuel management system. That can be either mechanical or preferably electronic. The system works as a reference point from the intake manifold to the fuel pressure regulator or the ECU, which will add fuel for every pound of boost.

While a supercharger upgrades engine power, it also requires power to make that power. The drain can be as high as 900 horsepower in a top fuel application.

Turbochargers

Turbochargers run off exhaust pressure. They have cleaner emissions because the exhaust gases are recycled. This is why some refer to turbocharging as “free horsepower.” A turbo engine power upgrade is highly efficient, lightweight, and works well at higher altitudes.

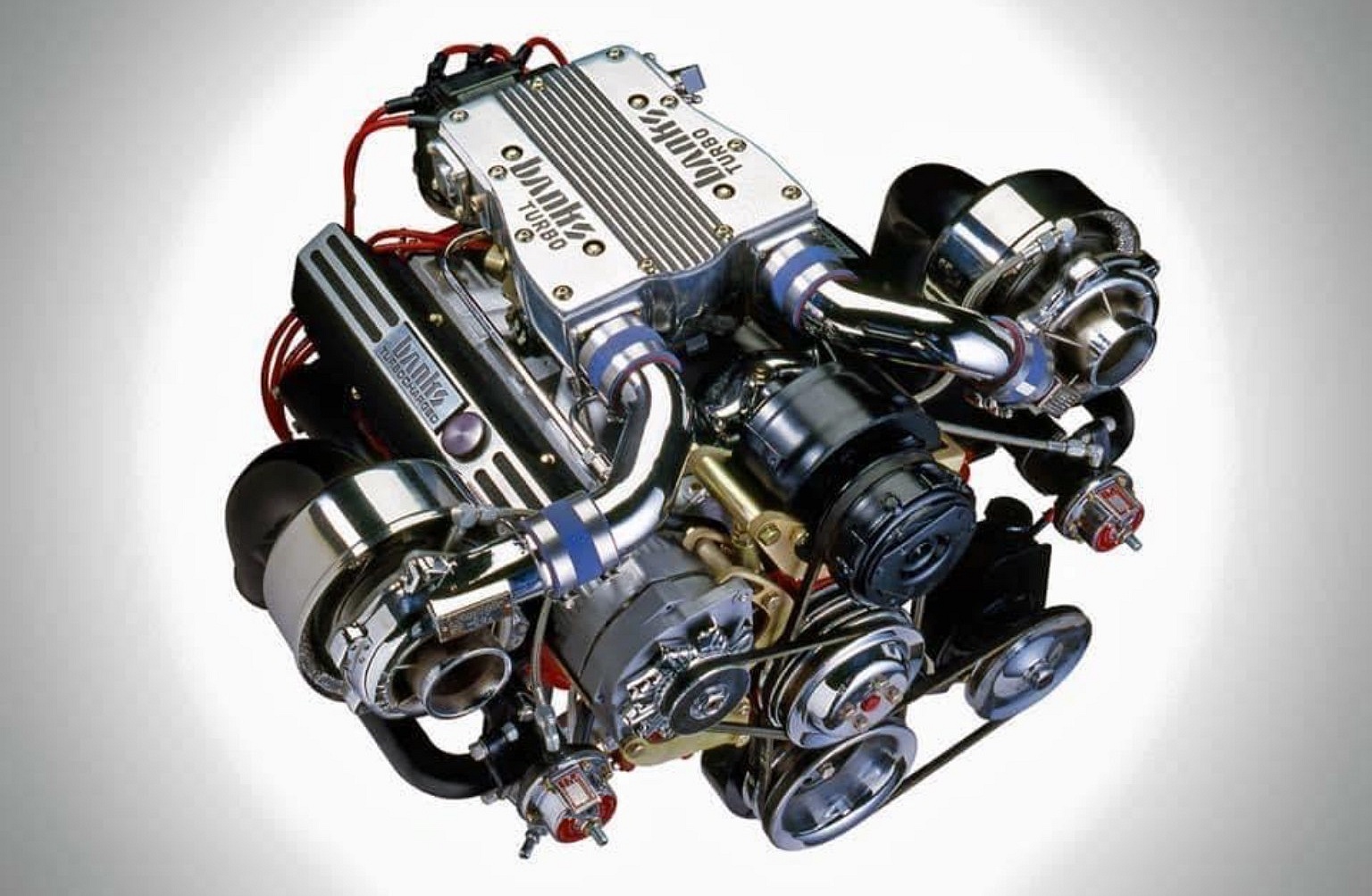

A tidy Banks Engineering dual-turbocharger install

A turbocharger installation can be challenging because you are modifying the intake system, the exhaust system, the fuel system, and the oiling system. With added air, you will need a fuel management system. Since the turbo uses exhaust pressure to spin, you must also modify the exhaust system.

Finally, the byproduct of pressure is heat, so be prepared to make room under the hood for an intercooler, which is a must. A well-engineered turbocharger kit designed for your specific vehicle will smooth the installation process.

Read this: How an Intercooler Works and Why You Might Want One.

Nitrous Oxide

Engineers first used nitrous oxide to upgrade engine power in aircraft because there’s less air at higher altitudes. These days, we use nitrous oxide to burn more fuel in cars. Nitrous oxide kits, which are easy to install, have been used by racers since the late 1970s.

Nitrous is injected into the intake, where it breaks down into nitrogen and oxygen molecules, allowing the oxygen to mix with the fuel for more potent combustion. Because the excess heat can damage engine components, it’s critical to use proper fuel management.

A trunk-mounted nitrous oxide bottle

Compressed Air Supercharging

Mickey Thompson, the famous 1960s race builder, first used compressed air supercharging in 1971. That’s more than a half-century ago, but it’s the newest power-booster on my list, and it’s definitely worth a look.

Compressed air systems are now more accessible to modern auto enthusiasts. It operates on the same core principle—more oxygen equals more power. A compressed air supercharger looks impressive because it’s introduced to the intake via mounted scuba bottles.

Compressed air superchargers add a massive amount of power.

I recently built an engine that uses two bottles on a 540 cubic-inch big-block Chevy engine. It produces a 2:1 boost, meaning for 10 pounds of boost, you only need five pounds of air. The system compresses the air, delivering it at -140° to the engine. The lower temperature makes it easy on parts because there is no detonation.