Contents

Generators vs. Alternators

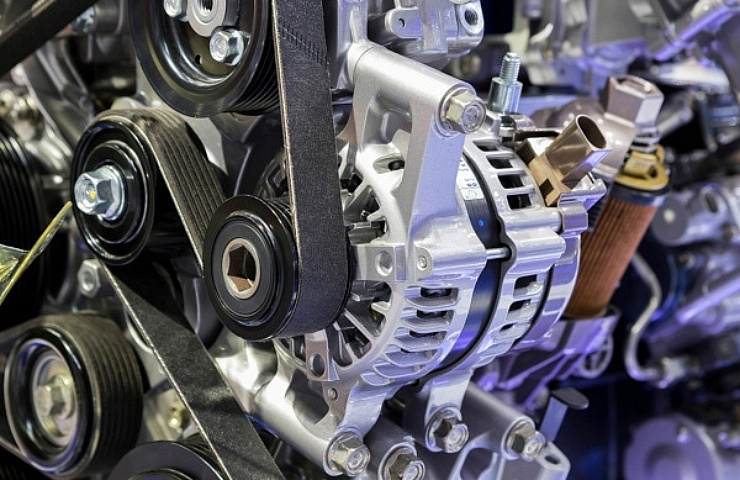

A typical modern car alternator

Two types of devices generate electrical power for automobiles: generators and alternators.

Generators were used in cars up to the early 1960s. They were big, heavy units that generated direct current (DC) power, the type of electricity vehicles use. Generators require speed to make electricity, so they don’t do much at idle. They use brushes that wear out often, plus they get very hard to turn the more power they generate, meaning more drag is put on the engine. This eats up horsepower and increases fuel consumption.

Shop now for automotive alternators and generatorsThe silicone diode changed that, allowing the changeover to alternating current (AC) alternators. These make power more easily and at lower speeds without as much drag. Because alternators create AC, as your home uses, the electricity needs to be converted to DC. A rectifier converts the AC to DC so your engine can use it.

An old style generator for a Ford 4-cylinder flathead engine

What the Alternator Does

As the engine spins, the accessory belt drives the alternator’s rotor. The rotor uses an alternating pattern of north- and south-pole magnetic plates. When the rotor is energized, it becomes an electromagnet. It spins inside a stator, a series of copper windings, and generates an alternating current.

The alternating current passes through the rectifier by way of three to eight silicone diodes. These diodes are one-way valve semiconductors. The current can only flow in one direction, which stops the alternating current from being able to reverse flow and become a direct current. If one of the diodes fails, the alternator’s output drops significantly. For instance, if a three-diode rectifier loses one diode, the alternator output drops by a third.

An external voltage regulator for ’70s-era Toyota cars and trucks

A regulator is used to control the alternator. Vehicles built before the mid-1970s had separate regulators with high failure rates. As technology advanced, the regulators moved inside the alternator, and they became more reliable. The regulator controls the alternator’s output by turning the rotor field off and on.

This on/off switching happens as many as 2,000 times a second. Many vehicles are rpm-controlled, meaning the alternator doesn’t start charging until the engine is revved up past 2,000 to 2,500 rpm. Some newer cars have changed to pulse-width modulation (PWM) control, so the alternator only supplies current as demanded. This reduces both drag on the engine and fuel consumption.

When an Alternator Fails

A dead battery can kill an alternator and vice versa. Too much draw on the alternator weakens it, and a faulty rectifier or regulator can over- or under-charge the battery, leading to its demise.

Your vehicle should have a battery voltage gauge on the dash. When the engine is running, this should show between 13.2 and 14.4 volts. Above 15 volts is bad, and below 13 volts is equally bad. The battery only maintains 12 volts, so if the alternator is not providing 13 to 14 volts, the alternator is not working and needs to be addressed.

Read: Signs of a Bad Car Battery vs. Alternator

How to Test an Alternator

A mechanic using a digital multimeter to check car battery voltage

If your alternator is not controlled by an electronic control module (ECM), follow these basic steps:

- Turn the engine off.

- Set a digital multimeter (DMM) to 20v DC

- Touch the DMM’s red probe to the battery’s positive terminal and the black probe to the negative terminal. You should read between 11.5 and 12.5 volts.

- Start the engine. Repeat the above test.

- The reading should jump to 13.5 to 14.4 volts. If the voltage is the same as before, try revving the engine up to about 2,500 rpm, holding it there for 30 seconds, and then retesting. Your alternator has an issue if the voltage still has not jumped to the low 14s.

Testing an ECM-controlled alternator requires specialized equipment such as a battery voltage tester and code reader to verify that the alternator and battery are working. Refer to a service and repair manual for your vehicle.

Find out: How to Test an Alternator (And Fix It!)

Shop now for automotive diagnostic toolsSigns of a Failing Alternator

There are a few telltale symptoms of a failing alternator. Some are more obvious than others.

Slow-Crank or No-Crank. If the engine won’t start because it isn’t spinning fast enough, the battery is usually the first to be blamed—about half the time. However, the alternator is responsible for the other half of the slow-crank or no-crank situations because it simply has not been charging the battery enough.

It takes a good 20 minutes of driving to recharge a low battery to the point that it will start the engine again. If you get a jump start and drive 30 minutes or more, and the car won’t start after shutting it off and trying to start it again immediately, then the alternator may be to blame. It needs to be tested to be sure.

Dimming or Fluttering Lights. When you drive the car, the headlights should be solid and not fluctuate at all. If they do, then the alternator may be struggling to operate. You are likely running on battery power alone and about to run out of juice.

Burning Smell. This is harder to pinpoint, but electrical burn has a specific smell. You must immediately stop driving and inspect the vehicle if you smell a faint ozone-burning smell.

An electrical fire in a car is a serious emergency that can burn down the entire vehicle. When an alternator overheats, it can start burning internally or overcharge the system and start melting wires.

Grinding or Whining Noise. The alternator has two bearings, one in front and one in back of the rotor. Eventually, these bearings wear out, and they are not user-serviceable. They start to groan, whine, or grind, so if you hear this noise, inspect the vehicle to locate it. If that sound is coming from the alternator, it is time for a replacement.

Discover: Why Your Car Won’t Start

Cost to Replace an Alternator

A v-belt alternator for older Chevrolet cars and trucks

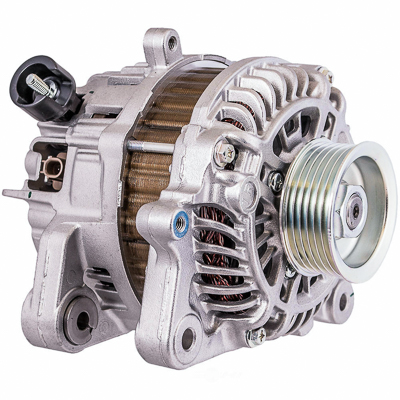

Depending on the location, replacing an alternator can be a simple 10-minute job or an all-day task. Most alternators cost between $150 and $400.

The charging system in your vehicle makes everything work. Without it, not much is going to function. Battery maintenance is the most significant factor for alternator health. If your battery gets low, use a trickle charger to top it off, especially during winter nights, when the cold can zap the juice from the battery and put a considerable strain on the charging system.

Shop now for alternators and wiring