Contents

A torque wrench is essential when tightening wheel lug nuts, suspension parts, camshaft timing belts, or just about any bolt or nut on a modern aluminum engine. It ensures that critical fasteners on modern vehicles are not over- or under-tightened.

Shop now for torque wrenchesHere’s the key: a torque wrench is a calibrated tool that can apply a designated load (torque) to a nut or bolt. The amount of torque depends on the amount of force applied to the tool’s handle and the length of the wrench, expressed in this formula: torque = force x length.

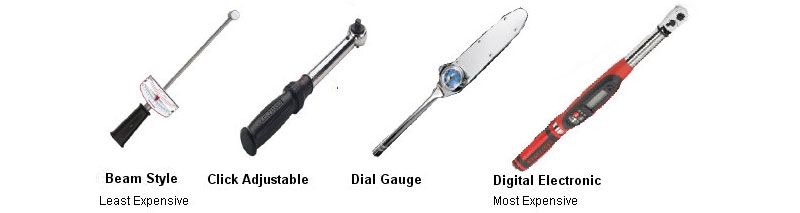

Four Styles of Torque Wrenches

There are four basic torque wrenches.

- A beam-style wrench has an indicator that sweeps across a gauge. You stop applying pressure when the needle is at the desired reading.

- A dial gauge wrench embeds a moving dial in the handle. As you apply pressure, the dial moves, indicating the force. You stop applying pressure when the dial indicates the desired torque. With either a beam wrench or a dial gauge wrench, nothing prevents a user from using more force on the wrench, so care must be taken.

- On a click adjustable wrench, you rotate a ring on the handle to set the desired torque. You’ll hear a “click” when you reach the pre-determined setting. At that point, stop wrenching.

- Digital wrenches are the top of the line. You can adjust the desired setting on a digital screen. As you apply pressure, the digital display reflects the increase. When the wrench reaches the desired setting, it sounds a confirming note, and the display confirms the applied torque.

A torque wrench indicates the torque on either a scale or display. That scale is calibrated in pound-feet, inch-pounds, or, for metric standards, Newton meters (Nm). A typical automotive torque wrench ranges between 10 and 250 pound-feet. These units have a half-inch drive. Torque wrenches with a three-eighth or one-quarter drive are for smaller fasteners requiring less torque and are calibrated in the 10- to 200-inch-pound range.

Shop now for torque wrenchesUsing a Torque Wrench with a Socket Extension

Proper Steps for Using a Torque Wrench

First, go online or consult the service manual to establish the exact torque setting for the specific fastener you are tightening. In other words, don’t guess. Unless otherwise stated, the published value will apply to clean, dry, undamaged threads. Never put oil on a fastener’s threads unless specifically directed to do so.

Next, screw in the fastener by hand until it is snug, then use the torque wrench to tighten fully.

Place your hand on the grip. On an adjustable or click-type wrench, pull up on the torque wrench, keeping your arm parallel to the fastener until you hear the wrench make the clicking sound. For a dial-type wrench, look at the pointer on the dial straight to ensure you get an accurate reading.

If you tighten multiple fasteners on a part, like wheel bolts, check for a specific tightening sequence to equalize the load. The order for multiple fasteners is usually side-to-side or opposite the last fastener torqued.

Shop now for socket setsTips to Maintain Your Wrench

Since the torque wrench is a precision tool, it can only be used to tighten a fastener. Never use it to loosen a fastener.

Most manufacturers package torque wrenches in a protective box. Store them in the box when not in use.

If you use a torque wrench only infrequently, consider removing the battery, if it has one.

Most can be professionally re-calibrated. If you suspect your wrench is inaccurate, compare it with another wrench first. Tighten a test fastener with the questionable wrench first, and then see if the other wrench confirms the same setting. If not, contact the manufacturer for a list of calibration shops and their fees.

Make sure to store adjustable torque wrenches adjusted down to their lowest setting so calibrations are not compromised by stretching the internal spring mechanism.

Torque wrenches are essential tools, often needed to ensure the correct parts installation. When properly cared for, a quality unit can last a lifetime.

Shop now for torque wrenches